2、 Description of assembly line technical requirements

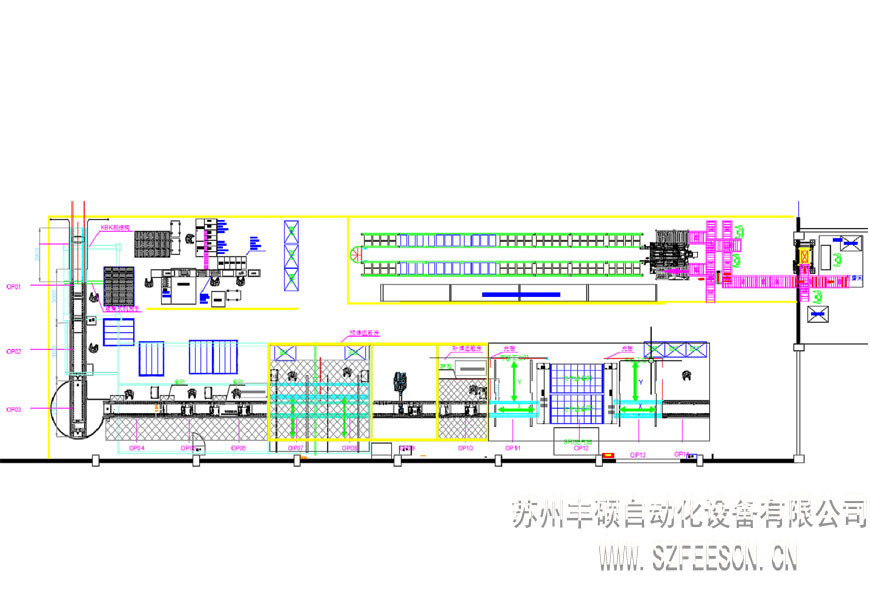

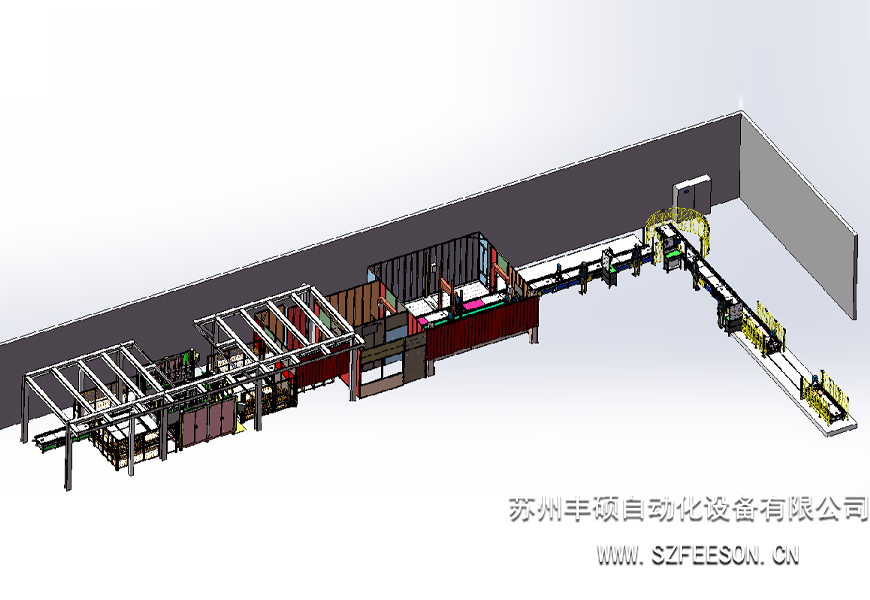

The assembly line is used to improve the production capacity of products. In order to save workshop space, the production line and the existing assembly line share the online and repair welding stations of the gas box shell, and are equipped with the same assembly tooling. The new assembly line is separated from the old line by a 3m wide logistics channel. The gas box is transferred from the old line buffer station to the new line by an AGV conveyor car. The number of stations set in the new assembly line is 14. The power of the transmission line is SEW reducer motor, The conveyor line is of aluminum profile structure, the support leg of the conveyor line is of steel profile, and the cover plate is of 3mm steel plate (except that 4mm thick checkered steel plate is required for the cross line operation station, the cover plate of other stations is of flat plate and plastic spraying treatment). The control mode of the conveyor line is: manual/automatic

1. Line configuration:

1) Length of conveyor line L=3.2m, height H=0.5m; SEW reducer motor (installed below the line body) is used as the power for 17 sections of the conveyor line. The transmission mode is reasonably designed according to the tooling structure. The conveyor line is made of aluminum alloy profiles, and the cover plate is made of 3mm thick steel plates; Install a set of pneumatic stopper (brand: Festo), and install a stopper at the inlet; Integrated design requirements for working table and control box:

2) The main function of the work table is to place standard parts, tools, display screen, scanning guns, etc. The work table is made of aluminum alloy frame (L=800mm, B=450mm, the height is refined according to the design), and the table top is covered with aluminum alloy plates;

3) The control box and the work table are integrated as a whole, and the occupied space on the table is reduced by reducing the overall size of the button. The control mode is manual/automatic, which controls the release of the air box and the air box on the transfer vehicle enters the OP01 station;

4) Set standard parts hanging plate and tool hanging plate, and reasonably set the position of display and scanning gun;

5) 220V power supply (with electric shock protection cover) and air source quick plug interface are installed on the side of the working table; The conveyor line has the function of accumulation and placement, and can store multiple air boxes at the same time (judged manually); This station is equipped with a set of KBK lifting manipulator (assembly manipulator with electric balance function) for the installation of LBS. The mechanical and manual installation is designed according to the shape of LBS. The travel of the manipulator is designed according to the installation position of the air box and the placement height of LBS parts. KBK tracks are made of aluminum alloy;