Product No.: fs-sz105

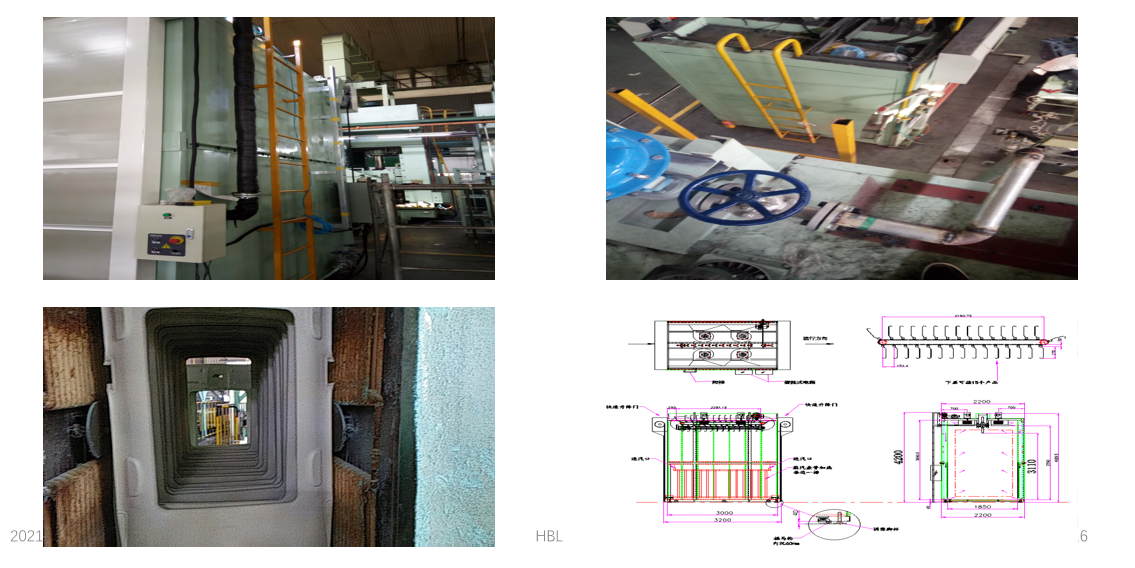

Scope of application: fs-sz105 automobile roof lining steam drying room (Wuxi Jixing)

Technical parameters of fs-sz105 automobile roof lining steam drying room

1、 Production process flow: manually transport the canopy base material from the spraying fixture to the drying room (placement positioning) - the canopy base material moves to the discharge end (placement positioning) after drying in the warehouse for a certain period of time - manually transport the canopy base material to the fabric fitting mold - repeat the above actions;

Manual touch; Start up: open the manual mode, carry air in the drying room, conduct heating and conveying operation, and close the door; Feeding: press the door open key, the door will rise, hang the product, press the door close key, and the door will close. The feeding repeats this action (at this time, the conveying will not stop until the end blanking sensor senses that a product line has stopped and waits for manual reclaiming);

Blanking: when the blanking sensor senses that there is a product, the conveying stops, the door rises and waits for blanking. After the manual blanking is completed, press the material end button and the door drops for conveying; Repeat this operation for blanking.

Automatic+manual mode (robot feeding, manual blanking) startup: open the automatic mode, the drying room runs, the heating is delivered at the same time, and the door is closed;

Feeding: the robot sends the feeding request signal to the drying room. After receiving the signal, the drying room senses the first hook and stops the conveying. The positioning cylinder descends and the positioning back door opens. At the same time, the robot sends the feeding signal. After receiving the feeding signal, the robot loads the material. After the feeding is completed and returns to the position, the robot sends a feeding end signal to the drying room. After receiving the signal, the drying room automatically closes the door, releases the positioning, and transports; When the second feeding request is not received, the conveying will run continuously until the product is sensed by the feeder 6 of the feeding induction technical agreement; If the blanking sensor senses the product, the same as the hook sensor senses the hook. At this time, the cylinder descends for positioning, the door opens, and waits for manual reclaiming. After the manual reclaiming is completed, press the reclaiming end button. After receiving the signal, the drying room closes the door, unlocks the positioning, and the conveying operation waits for the next cycle