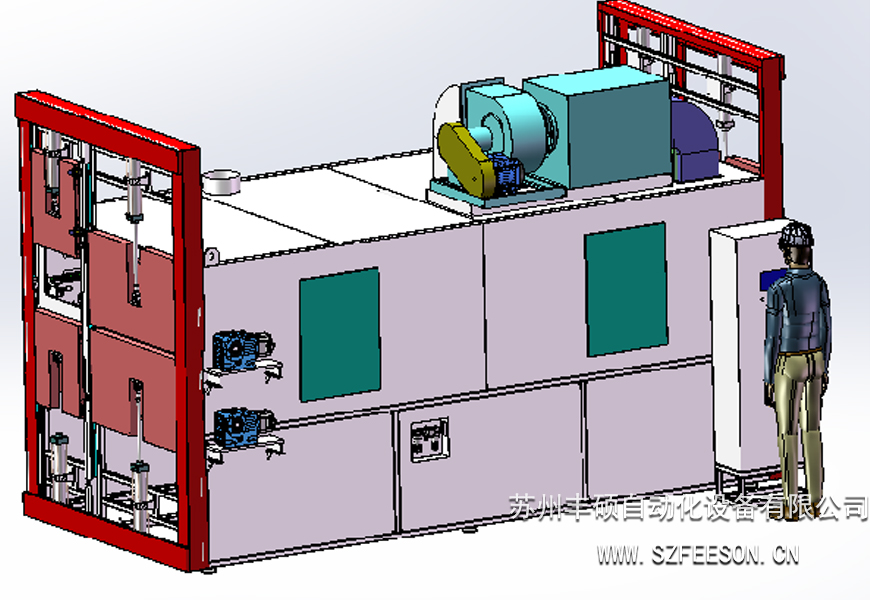

2、 Specifications: 4500L × 2150W (external width, excluding motor) × 2250Hmm (total height)

3、 Equipment structure:

There are 2 layers of curing drying channel, 4 channels in total, and 2 layers of cooling channel. When looking along the product running direction, there are 2 channels in total. The left side is the heating curing channel, and the right side is the heating curing channel

Cooling channel; The conveying line on the first floor is 600mm high, and the second floor is 1070mm high; Adopt 2.5 times speed chain for conveying, and cooperate with the cylinder to prevent heating

Adopt backpack type centralized heating, hot air circulation and horizontal wind;

4、 Description of basic configuration and structure

1. One set of power is used for the power heating drying channel, and the upper and lower layers of the two channels are respectively powered. The motor is a K series reducer motor of Taiya or the same brand, with the model of KA47, the output speed of 20 RPM, the torque of 338n. m, the power of 0.75 KW, the linear speed of 10-15.0 M/min adjustable, and the frequency control.

2. One set of motor is used for cooling and conveying, which is K series reducer motor of Taiya or the same brand. The model is KA37, the output speed is 20RPM, the torque is 167n. m, the power is 0.37KW, the linear speed is 10-15.0M/min adjustable, and the speed is adjusted by frequency conversion. The cooling furnace adopts air conditioning cold air cooling, circulating air, side up supply and side return, air volume 5000m3/H

3. The fuselage adopts 2.5 times speed special aluminum rail, and the frame adopts 40 × 40 (mm) steel pipe welding, with galvanized adjustable leg cup

4. The conveying chain is made of carbon steel 2.5 times speed chain with a pitch of 25.4mm. The chain wheel is made of nine teeth with a pitch of 25.4mm. The tooth tip is quenched. The transmission shaft is made of 45 # steel and its surface is chrome plated